Should You Make Your Own Solar Panels

We do not recommend making your own solar panels, although it might seem easy to configure a panel with all of the proper materials. Errors in building your own panels, like starting a fire, outweigh the benefits of DIY solar panels.

It is best to rely on professionally built solar technology because they are built with rigorous standards and tested for durability. Working with a professional solar installer is an important step to making sure your solar panels are made with high-quality materials that will provide solar power for their 25-year warranty, or more. Solar panels are one of the best energy sources for reducing carbon dioxide from fossil fuels so adding them to your home is a great way to be part of the clean energy future.

How Manufacturers Are Improving Solar Panel Efficiency

Solar panels are made up of many components, and there are similarly many opportunities to improve the solar panel manufacturing process.

Manufacturers can make solar panels more efficient in two basic ways:

- Improving the solar cells themselves

- Improving the way the cells are placed in the panel

There is an alphabet soup of acronyms and buzzwords being floated around about improvements in technology coming down the pipeline. These are just a few of the improvements that different manufacturers use to increase the efficiency of their solar panels.

How Much Copper Is In A Solar Panel

Wind and solar photovoltaic energy systems have the highest copper content of all renewable energy technologies. A single wind farm can contain between 4 million and 15 million pounds of copper. A photovoltaic solar power plant contains approximately 5.5 tons of copper per megawatt of power generation.

Read Also: What’s The Cost Of Installing Solar Panels

Frequently Asked Questions: What Are Solar Panels Made Of

What products are solar panels made of?

Solar panels are composed of numerous solar cells, a set of wiring to connect those solar cells to a conductive material base, a glass or plastic protective casing for both individual cells and the whole panel, and a frame used to house all of these components. The material components typically include silicone or another semiconductor material, metal, plastic or glass, and wiring apparatuses.

Is living near a solar farm dangerous?

Solar farms do not produce any emissions, noise, pollution or other outward hazards. They also won’t impact the level of sunlight experienced by those living near them. The hazardous materials sometimes discussed regarding solar panels are safely contained within the panels themselves and are only a concern when determining how to dispose of or recycle those panels, so they pose no danger to those living nearby.

What toxic materials are in solar panels?

Some of the metal and chemical materials in a solar panel can be toxic and hazardous if exposed to people, including panels that may have cadmium telluride, arsenic, hexavalent chromium coatings, copper or selenium. In typical operation, though, these materials are securely contained and don’t pose any direct risk.

What is the back of a solar panel made of?

The back of a solar panel, known as the backsheet, is made of a polymer or plastic combination. It provides insulation from the electrical components of the panel.

Transparent Flexible Solar Cells

Previous imageNext image

Imagine a future in which solar cells are all around us on windows and walls, cell phones, laptops, and more. A new flexible, transparent solar cell developed at MIT is bringing that future one step closer.

The device combines low-cost organic materials with electrodes of graphene, a flexible, transparent material made from inexpensive and abundant carbon sources. This advance in solar technology was enabled by a novel method of depositing a one-atom-thick layer of graphene onto the solar cell without damaging nearby sensitive organic materials. Until now, developers of transparent solar cells have typically relied on expensive, brittle electrodes that tend to crack when the device is flexed. The ability to use graphene instead is making possible truly flexible, low-cost, transparent solar cells that can turn virtually any surface into a source of electric power.

Researchers have made significant advances over the past decade toward developing transparent organic solar cells. But theyve encountered one persistent stumbling block: finding suitable materials for the electrodes that carry current out of the cell.

Its rare to find materials in nature that are both electrically conductive and optically transparent, says Professor Jing Kong of the Department of Electrical Engineering and Computer Science .

Graphene challenges

A smooth graphene transfer

Putting the electrodes to the test

Flexible substrates, bending behavior

Future goals

Don’t Miss: Does Pine Sol Kill Mosquitoes

How Are Solar Panels Made

Although solar panels do the challenging job of generating solar energy from the sun, building a solar panel is pretty simple when built professionally in a well-run factory. The main components of a solar panel are solar cells, silicon, metal, and glass. Each of these components is then compiled to form a solar panel that can generate renewable energy.

Allow us to take you through the step-by-step process of how and where solar panels are made, from the photovoltaic cells to the frame, before they are shipped out to be installed on your roof by a contractor.

Solar Funhow To Make A Solar Panel With Cd Step By Step Guide

There are so many interests among general people that they keen to know how to make a solar panel with CD?

Is it just a myth to make a solar panels with CD?

Is it still possible yet or not?

Dont be confused at all & looking around in other sources here in this write up you will get all the details of how to make a solar panels with CD?

It is nifty little fun idea to repurpose the old unwanted CDs, and It is an easy venture to witness to observe the futuristic phenomenon of solar power as well.

After reading this article, you will know how it is possible to build your solar panels with CD. This particular piece will tell you how to make homemade solar panels with CD to produce secondary usefulness as well.

Youre wondering, right? Lets read & explore-

Lets deep dive!!

Read Also: How Much Does A Solar Power System Cost

Disadvantages Of Using Solar Cells

Disadvantage of using solar cells are

- The surface of the cell has to be large in order to produce reasonable amount of electrical energy.

- When the sun goes into hiding in the clouds amount of energy generated will be cut down.

- They cannot be employed as energy source because of fluctuations in the amount of energy generated.

Glue The Copper Wire Into The Cd

Simply glue the end of the copper wire near the center hole of the cd, then extend the copper wire to the end of the cd, then bring it back to the center.

Repeat this step while gluing each copper wire to the cd until you cover most of it.

In the end, the cd should look like a flower.

Note: Make sure to leave the copper wires till they dry before proceeding to the next step.

Also Check: How Much Is A 5kw Solar System

How To Make A Solar Panel With A Cd

In this little short guide, we are going to show you how to make a solar panel with a CD. Its great for a science project for kids, high school students and even adults for practical educational applications.

This guide will teach you how to repurpose these CDs into solar panels and how to generate electricity.

Lets get started!

What Makes Up A Solar Panel

Solar cells are made out ofsilicon wafers. These are made out of the element silicon, a hard and brittle crystalline solid that is the second most abundant element in the Earth’s crust after oxygen and naturally converts sunlight into electricity.

Like other crystals, silicon can be grown. Scientists, like the ones at Bell Labs, grow silicon in a tube as a single, uniform crystal, unrolling the tube, and cutting the resulting sheet up into what are known as wafers.

“Visualize a round stick,” Vikram Aggarwal, the founder and CEO of EnergySage, a comparison-shopping marketplace for solar panels, tells Popular Mechanics. That stick is cut like a “pepperoni, a roll of salami cut thin for sandwichesthey shave them very thinly,” he says. Thats where it has historically been very difficulteither too thick, a waste, or too thin, making them not precise and prone to cracking.”

The backup of Vanguard 1, the first ever satellite to use solar power. The backup rests in the Smithsonian Air & Space Museum.

They try to make these wafers as skinny as possible, to get as much value out of their crystal as possible. This type of solar cell is made out of mono-crystalline silicon.

And it worked. Just four years after the first working solar cell was developed, on March 17 1958, the Naval Research Laboratory built and launched Vanguard 1, the world’s first solar-powered satellite.

Recommended Reading: How Much Energy Can Solar Panels Store

Proper Way Of Tinning:

For tinning, apply solder to the 4 from the top of the facing side of the tab ribbon. Then flip the tab ribbon, and apply solder covering 4 from the end opposite to the first end you have tinned.

The ½ in the middle of both side of the tab ribbon will remain free from tinning as this area will be crimped as showed in diagram B of the above picture.

The end product will be a piece of tab ribbon tinned on one side from the top to the 4, and the other side tinned 4 from the end.

The reason for that is, the tab ribbon will connect the positive or back side of the cell to the negative or front side of the cell.

- Back Side = Positive Side

- Front Side = Negative Side

Connect The Insulated Electrical Wire

Once the Zener diodes have been soldered to the copper wire, its time to connect the insulated electrical wire to your DIY CD solar panel. You can use a knife or small blade to clean up the very ends of the wires to form a better connection.

Here, you will use the soldering iron once again to fuse together the two remaining copper wire ends to the insulated electrical wire ends. After this step, you are essentially done creating your simple CD solar panel. All that you have left to do is test it out!

Also Check: What Materials Are Needed To Make Solar Panels

Purchase Additional Solar Equipment Like Inverters And Racking

If you do not trust yourself to build solar panels from scratch, you can purchase a solar panel kit which will come with more specific instructions to help secure your panels. Purchasing a solar kit might actually be more useful since it will include racking already.

Racking is tricky, you will need to determine which racking equipment works for your specific roof type or ground mount. There is almost an overwhelming amount of options of clamping and mounting equipment available if you look at wholesale distributor sites.

Glass In Solar Panel:

You can use different materials to protect solar panels. One of the materials you can use is the low iron tempered glass. It has good light transmission and doesnt break readily. However, low iron tempered glass is expensive.

You cannot buy tempered glass and cut it according to your panel size. If you do so, it will shatter. You have to order the exact size according to your panel size.

Dont use a regular glass window because it has poor light transmission qualities for solar cells. It also shatters easily with hail.

Tempered glass is also five to six times stronger than regular window glass.

Don’t Miss: Can You Recycle Solar Panels

Voltage And Distance To The Battery:

In most commercial plots, high current cells are connected in series to produce enough voltage to charge a 12-volt battery system. Of course, you can configure cells to produce 24 volts and 48 volts in a panel.

Higher voltage allows great travel with less voltage drop. If the distance between the panel and battery is around 100 feet, then you may need 24-volt panels. If the distance between the panel and battery is around 300 feet, then you need a 48-volt panel.

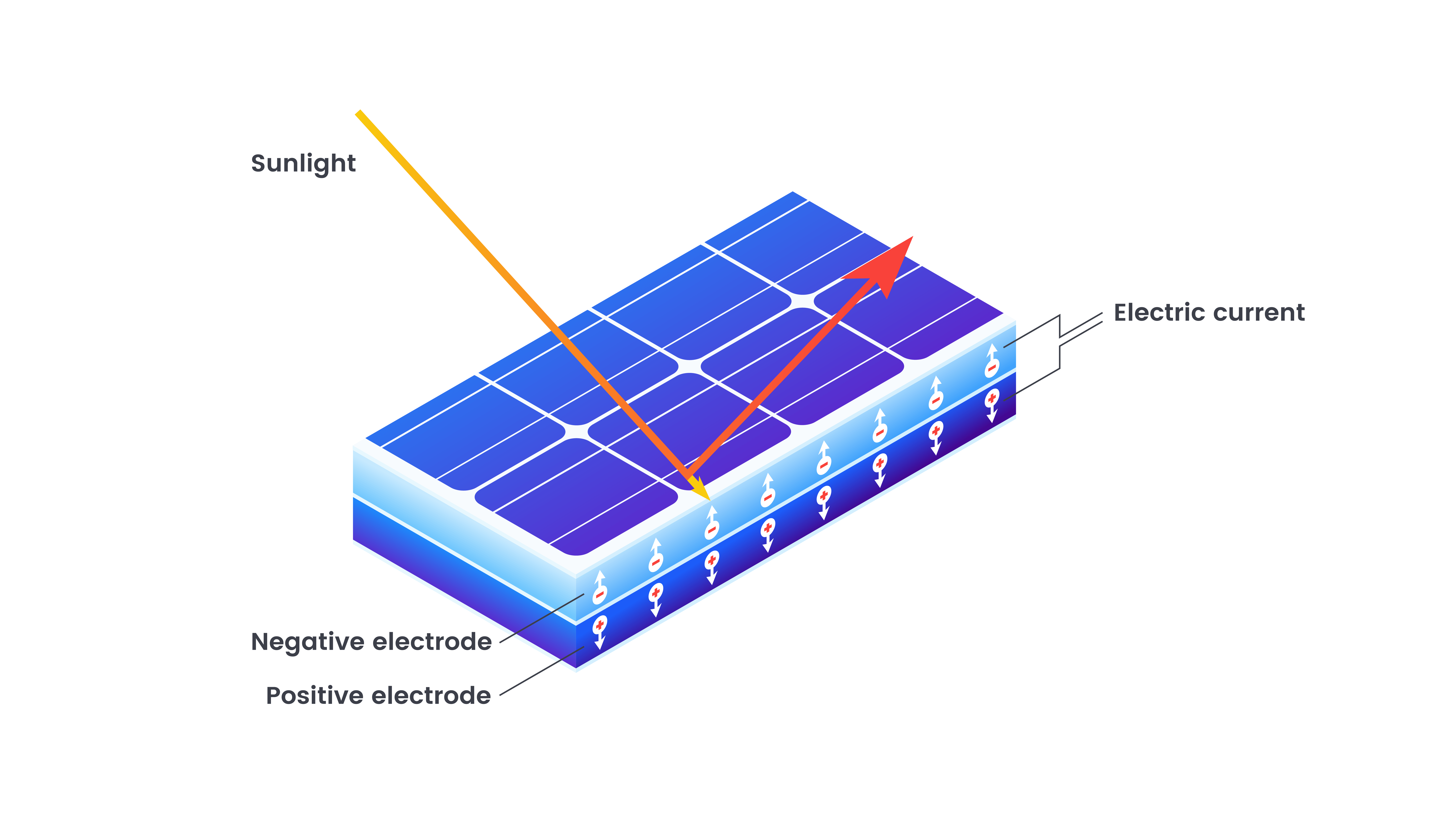

How Solar Cells Work

You’ve probably seen calculators with solar cells — devices that never need batteries and in some cases, don’t even have an off button. As long as there’s enough light, they seem to work forever. You may also have seen larger solar panels, perhaps on emergency road signs, call boxes, buoys and even in parking lots to power the lights.

Although these larger panels aren’t as common as solar-powered calculators, they’re out there and not that hard to spot if you know where to look. In fact, — which were once used almost exclusively in space, powering satellites’ electrical systems as far back as 1958 — are being used more and more in less exotic ways. The technology continues to pop up in new devices all the time, from sunglasses to electric vehicle charging stations.

The hope for a “solar revolution” has been floating around for decades — the idea that one day we’ll all use free electricity from the sun. This is a seductive promise, because on a bright, sunny day, the sun’s rays give off approximately 1,000 watts of energy per square meter of the planet’s surface. If we could collect all of that energy, we could easily power our homes and offices for free.

In this article, we will examine solar cells to learn how they convert the sun’s energy directly into electricity. In the process, you will learn why we’re getting closer to using the sun’s energy on a daily basis, and why we still have more research to do before the process becomes cost-effective.

Don’t Miss: Where Do Solar Panels Come From

Attaching Tab Ribbon To Cells:

Each solar cell will have 4 pieces of tab ribbon. Two pieces of tab ribbon will be on back side , and two pieces of tab ribbon will be on the front side .

In the starting, you have to solder two pieces of tab ribbon on the back of each cell. The cell-to-cell connection will be soldered later. For reference, see the picture below.

Each solar cell comes with the soldering strips on both sides. You have to solder tab ribbon on soldering strips .

You have to place the tinned side of the tab ribbon on one of the soldering strips and run your hot solder iron tip to the length of the tab ribbon. This will melt the solder that already presents on the tinned tab ribbon and attach tab ribbon with the solar cell.

It is good to practice soldering first on the dead cells if you never did soldering before.

Although soldering is not difficult as all you have to do is to keep your hot iron solder tip constantly running as it is melting tin and dont stop at one place as extra heat and destroy the solar cell.

Also, dont apply too much pressure against the solar cells.

It is good to hold tab ribbon with the piece of wood, or any other device while soldering tab ribbon on the solar cell. This is because often tab ribbon moves out of alignment.

Soldering is easy after several tries. As you practice more, you will able to solder fast and straight.

Chapter 4 Making A Solar Panel:

With enough tools and a proper technique, you can make a solar panel that is comparable or better with the one available in the market. So, In this fourth chapter, I am going to give you each and every step on how to make a solar panel.

Once you are done building your first solar panel, you can improvise with other designs and materials to improve the shape and performance of your solar panel. You can also build a custom-designed solar panel by using the techniques and steps I have provided in this chapter.

Except for the PV cells, tab and bus ribbons, other tools and materials required for building this solar panel are easily available in any hardware store. You can get PV cells, bus and tab ribbons from Amazon or eBay or Aliexpress.

Following is the list of tools, materials, calculations, and steps for building a series wired solar panel.

Here is the list of tools and material required:

| Materials Required |

|---|

| 2-position barrier block |

| Fiberboard for layout board |

Don’t Miss: When Should A Baby Start Solid Food

How Can I Make A Simple Solar Panel At Home With A Cd: Diy Step By Step Guide Of Making Simple Solar Panel With Cd

The traditional solar photovoltaic panel produces electrical power through the photovoltaic process .

In comparison, the solar thermal panel reflects the suns rays to heat a particular object, fluid, or area.

Although they do not convert the suns rays into electricity, they are crucial to the solar platform.

You do not require battery or inverter integration with the solar panels.

The process is less sophisticated than that of a grid-connected system. The technology is not any less valuable than that of the photovoltaic generation as well.

Follow the procedures below to know how do you make a solar panel CD: in only six steps

The Production Of Crystalline Solar Modules

A solar PV module consists of solar cells, glass, EVA, backsheet and frame. Learn more about the components and the process of manufacturing a solar panel.

There are 3 types of solar panels available on the market:

-

monocrystalline solar panels

-

polycrystalline solar panels

-

thin film solar panels

Thus, at cell structure level, there are different types of material for manufacturing, such as mono silicon, polysilicon or amorphous silicon . The first 2 kinds of cells have a somewhat similar manufacturing process. Read below about the steps of producing a crystalline solar panel.

Recommended Reading: Is There A Government Scheme For Free Solar Panels