What Are The Types Of Solar Power Systems

There are three main types of solar power systems:

- Grid-tied systems: The most popular solar system type the home is connected to the grid so it can use electricity from the utility when the solar panels arent producing enough energy to power the home

- Hybrid systems: Also called solar-plus-storage systems the solar panels are paired with a solar battery to store energy for the home to use later on or during a power outage, and the home is also connected to the grid

- Off-grid systems: There is no connection to the grid and the home runs entirely off of energy generated and stored on site

Learn more: Solar power system types

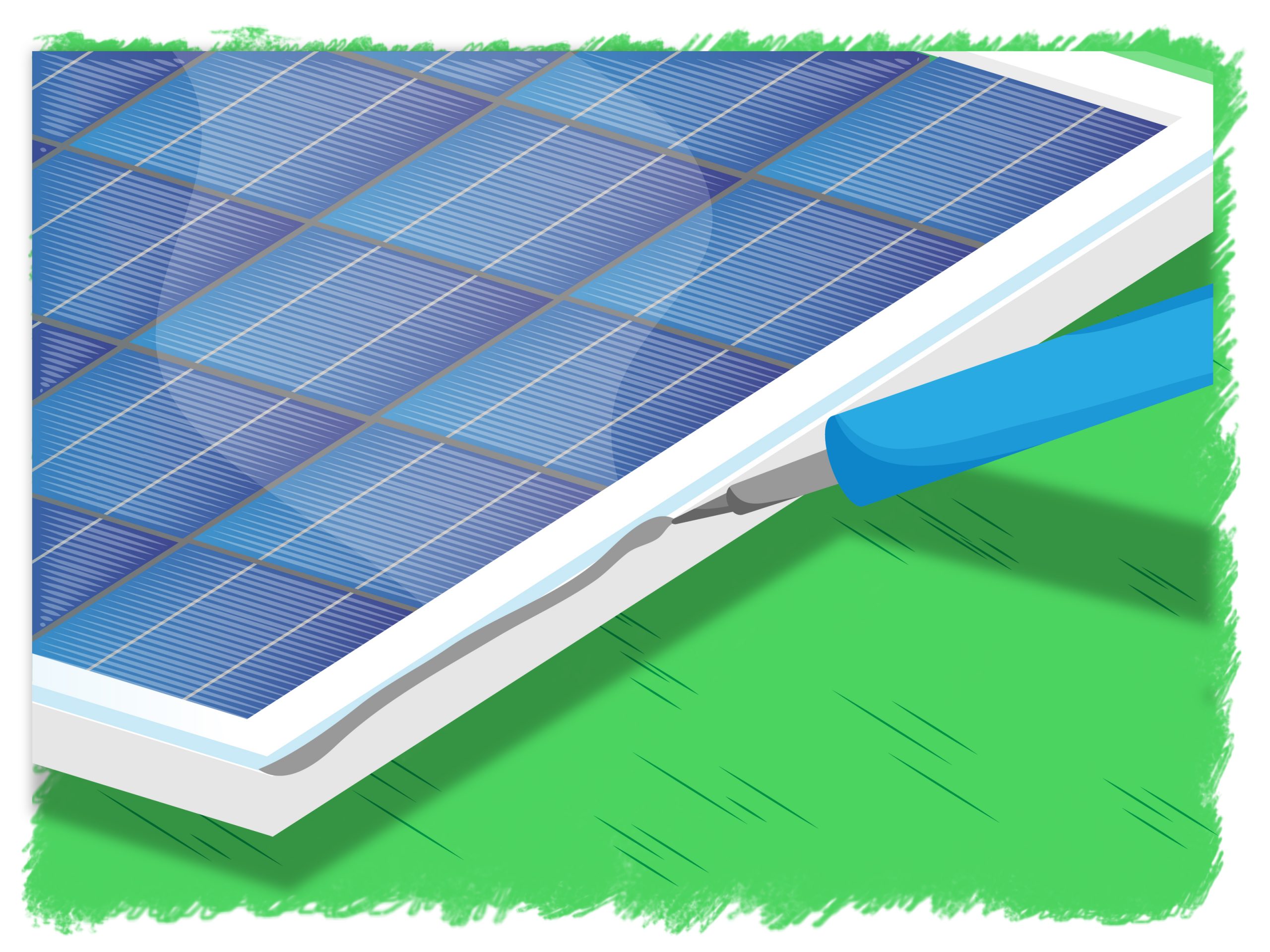

Install A Backsheet Front Glass Layer And Frame

A backsheet is installed to the bottom of the solar cells for protection, usually made from an ultra-durable plastic material. Next, a thin glass sheet is installed on top of the solar cells to filter the sunshine into the solar cells. These parts are held together by a glue called ethylene vinyl acetate . All of these components are confined by a metal frame which latches onto mounting clamps on your roof.

Choosing Solar Cells Carefully:

As mentioned previously, solar cells come in different sizes and types. The price of solar cells varies depending on their output and manufacturer. When you are purchasing solar cells, then make sure you ask for broken and dead cells. These cells are great for practicing soldering and learn how to handle them.

However, dont use any substandard solar cells in your panel. Sometimes cells that have hairline cracks appear to be functioning well, but when they go into the panel, they break easily because the panel is exposed to the weather.

If any solar cell breaks then the whole panel has to be taken out to replace the bad cells. This is why you have to inspect solar cells even before soldering them.

If you are working with PV cells, then you have to be very gentle with them as they can break very, very easily. During soldering, many people break them by applying too much pressure on them. Solar cells are heat-sensitive that is why it is essential to test soldering on a broken or dead solar cell before do soldering without damaging the cells by applying too much heat.

Also Check: Can I Get Sole Custody Of My Child

Purchase The Components That Make Up A Solar Panel

You will need:

Image source: Energy.gov

Solar cells are what converts the suns energy into electricity, each solar panel consists of about 36 solar cells.

Pre-soldered wiring

Image source:

Buying pre-soldered tabbing wire will cut some steps out of the process, but you will still need a soldering iron to solder the wiring to the back of the solar cells and string the wire correctly to connect the solar cells.

Non-conductive material to attach the cells to, like wood, glass or plastic

For DIY solar panels, wood usually works best as backing because it is easy to drill holes for the wiring. Once you have your solar cells wired together, you can glue these to the wood backing and then attach all of the wires and solder each solar cell together.

After wiring, you then connect these wires to a charge controller, which regulates the volts of energy. Wood can also be used to build a box to protect the solar cells and then to lay the plexiglass on top for moisture protection.

Seal the solar panel with plexiglass

Once your solar cells are wired and glued to the wood backing, you need to seal them with plexiglass for protection from heat, debris, and moisture.

Sand Is Converted To Crystallised Silicone

We now know what is used to make solar panels. However, making silicon from sand uses a lot of energy and is a costly process. Crystallised silicon is made from sand at a very high temperature in a furnace. The method of heating the sand in the furnace creates solid silicone rocks, which are collected from the bottom once it has cooled.

Don’t Miss: How Much Does Solar Energy Save

What Are Solar Cells

Solar cells are also known as photovoltaic cells , which work to generate electricity directly from sunlight. This is different to photovoltaic thermal cells , which work to provide heat for water in the home. Photovoltaic cells are connected electrically, and neatly organised into a large frame that is known as a solar panel. The actual solar cells are made of silicon semiconductors that absorb sunlight and then convert it into electricity.

Currently, solar panels that are used for domestic purposes are only able to take around 20% of the sunlight that they receive and turn it into electricity. This is what is known as solar efficiency. There are several other forms of solar cell available that are used for commercial and industrial purposes. These are able to have an efficiency rating of up to 40%, but they do tend to be more expensive than domestic models.

One of the great things about solar technology is the fact that advances in the field are constantly being made, raising the overall quality and efficiency. It is expected that this will only increase with further research and development. Similarly, as these aspects increase, the price of solar panels is expected to keep falling making them available to a much wider number of people.

The Formation Of Ingots

The rocks of crystallised silicone that are collected from the bottom of the furnace are then melted together. This process forms ingots, which is essentially a block of metal in a solid cylindrical shape. When the silicone is melted together, the machine operator ensures that the atoms align throughout the process and infuses boron. The infusion of boron gives ingots positive electricity polarity, which is essential later in the process.

Also Check: How Many Amps Does A 300 Watt Solar Panel Produce

The Materials That Make Up Solar Panels

Solar panels are made from a combination of two elements: silicon and silver.

Every solar panel is actually composed of many individual solar cells. The cells themselves are nothing more than pieces of silicon.

Thankfully, silicon is highly abundant in the environment, so environmentalists can rest easy knowing that the Earth isnt being depleted of this important element.

Silicon in the solar cells is able to absorb the energy from the sun and actually convert that energy into electron energy.

Once the electrons begin flowing between the layers of silicon, its up to the conductor within the solar panel to actually use the energy thats been generated.

Silver happens to be the element thats most widely used in solar panels because almost all of the energy thats generated from the solar rays which hit the cells can actually be used.

This results in less waste in terms of heat and energy.

Choosing The Right Solar Panels For The Job

If youre limited on space for your DIY solar project, monocrystalline panels are the best option due to their greatest efficiency and similar cost to their polycrystalline cousins.

Polycrystalline panels may be suitable if space is not an issue and youre trying to reduce costs even in small ways.

Thin films arent suitable for small-scale solar installation projects, nor are they worth it.

Recommended Reading: Can An Llc Be Considered A Sole Proprietorship

Testing Solar Cells Output:

Before constructing the panel, you need to test each and every cell that you are going to use in your project. If you are working with off-spec, then cells need to be categorized in low, medium, and high output. One low current cells can bring the output level of other high current cells to the low rating.

Although, you dont need to get the exact output from each cell, but they should be a level of what the panel is capable of producing.

For the best results, cells need to be tested in the bright sunlight when the sun reaches above your head. But, you can test the output level of cells at any time of the year. Keep in mind, the output level will vary according to environment and weather.

Glass In Solar Panel:

You can use different materials to protect solar panels. One of the materials you can use is the low iron tempered glass. It has good light transmission and doesnt break readily. However, low iron tempered glass is expensive.

You cannot buy tempered glass and cut it according to your panel size. If you do so, it will shatter. You have to order the exact size according to your panel size.

Dont use a regular glass window because it has poor light transmission qualities for solar cells. It also shatters easily with hail.

Tempered glass is also five to six times stronger than regular window glass.

Read Also: Should I Go Solar In Arizona

Silicon The Material Of Choice For Solar Panels

While according to Shockley and Queisser, the maximum theoretical solar conversion efficiency for a single p-n junction photovoltaic cell is achieved at a bandgap of 1.34 eV, silicon with a bandgap of 1.1 eVis used in approximately 90% of solar cell semiconductors sold today. Silicon PV comes in a number of different forms:

- Crystalline silicon

Crystalline silicon is the most common material used in solar cells. The lifespan of crystalline silicon cells is more than 25 years without deterioration, making it ideal for industrial solar power generation. It yields an energy conversion efficiency of up to 22%, the highest of all the currently mass-produced panels.

To improve efficiency even further by reducing reflected light, crystalline silicon is coated with chemicals such as silicon nitride or titanium dioxide.

- Amorphous silicon

Amorphous silicon is silicon without a crystalline structure. It is used to create a thin-film solar cell and is commonly found in smaller solar panels such as those on calculators or to power private homes.

The cells are manufactured by vapour depositing silicon in a very thin film onto a metal or glass frame. Amorphous silicon solar panels only achieve an efficiency of around 7%, due to a degradation of the material when first exposed to sun rays.

How To Build A Battery Bank For Solar

You can build your own battery bank to compliment your solar panel. Below are some basic steps you can follow to design and create your own battery bank.

The load is basically the amount of electricity you typically utilize on a daily basis. This can easily be found out by looking at your electricity bills for the usage of the last 12 month. Divide that amount by 365 to get the daily usage value.

After calculating the load, the next step is to decide how much backup power you need. Generally, people want a backup power of 2-4 days.

There is two way to connect multiple batteries together. Both ways have their own pros.

In Series

Batteries are connected in series by connecting positive terminal of one battery with the negative terminal of the other. This arrangement results in an increased voltage value.

In Parallel

Batteries are connected in parallel by connecting the positive terminal of one battery with the positive terminal of the next . This arrangement adds ups to the total capacity of the battery bank by increasing amp-hours.

The inverter is an important part of a solar panel. It converts the DC output of the solar panel as well as the power stored in batteries into usable AC. The inverter does not have storage capacity but it should be big enough to handle the maximum load that is put on it at an instance when converting the power.

Also Check: How Much To Install Solar Power System

Other Forms Of Solar Panels And Solar Power

There are emerging technologies in solar that present possibilities to create a step change in the efficiency of panels. These include graphene coating of solar cells, lightweight panels that dont use glass and are flexible. To see a more indepth review of the different types of solar panels and the different brands see this article.

Additionally there are alternate forms of solar power such as Concentrating Solar Power , where instead of solar panels, mirror panels are used to focus sunlight on a central tower where water is heated to high temperatures and is converted back to energy through steam turbines. Solar thermal panels work slightly differently as well, where the water runs through the panels in copper tubing that heats the water while it runs through the panel and returns to the hot water tank.

Compare quotes from up to 7 pre-vetted installers in your area now.

Building Your Panel Box

Don’t Miss: How Much To Add Solar Panels To House

Summary List Of Materials In A Solar Panel

So after all of that detail, we can write down a solar panel material list.

- Solar cell Crystalline silicon , Silicon Nitride

- Solar Cell Sealant Silicon Rubber Or Ethylene-Vinyl Acetate

- Backsheet Mylar Or Tedlar

- Cover -Glass

- Cabling Aluminum Or Copper, Moisture And Heat Resistant Thermoplastic

Note that this is a list of the components that make up domestic solar panels. Some commercial solar panels operate in a slightly different way and are manufactured from other materials.

Its also important to note that solar technology is advancing all the time. In the near future, we may not need to rely so much on silicon for solar panels since other semiconductors show great promise. Heres a good video looking at some prospective new solar technologies.

We welcome your questions or comments about this article on the materials that make up solar panels.

4.65

So What Does Nrel Say On The Numbers

Even ten years ago, this study said it takes about 2 years of energy generation to pay back the energy used to make the solar panel. Then it makes energy with no energy cost at all, for the rest of its life. So, a solar panel will make many times more energy than it takes to make it.

To calculate payback, Dutch researcher Erik Alsema reviewed previous energy analyses and did not charge for the energy that originally went into crystalizing microelectronics scrap. His best estimates of energy used to make near-future, frameless PV were 600 kWh/m2 for single-crystal- silicon modules and 420 kWh/m2 for multicrystalline silicon. Assuming 12% conversion efficiency and 1700 kWh/m2 per year of available sunlight energy , Alsema calculated a payback of about 4 years for current multicrystalline-silicon PV systems. Projecting 10 years into the future, he assumes a solar grade silicon feedstock and 14% efficiency, dropping energy payback to about 2 years.

And is anyone paying any research scientists to run the numbers on whether it takes more energy to build all these 50-ton coal mining trucks, and drive the coal to a railroad and shovel coal on it and burn it in power stations to determine if all that takes more energy than it generates when it gets there? Anybody? Crickets.

Read Also: How To Save Solar Energy

Materials That Make Pv Solar Panels

Solar photovoltaic is the latest and fastest-growing trend in the market. One of the reasons attributed to this is the ability to reduce ones electricity bills. The environmental benefits are also many and impactful. Understanding solar panel materials and how they work is essential if you are going to adopt solar energy.

Various components make up solar photovoltaics. The most important is the silicon cells. In this article, we are going to look at the solar panel raw materials in detail.

What Are The Items Needed To Make A Solar Panel System

Solar panel systems require more components than just a set of solar panels. While you can theoretically wire your panels straight to the device you wish to power, this may fail to power some or all of your devices. To set up a stable and flexible solar power system, you need solar panels, a charge controller, a battery and a power inverter.

Don’t Miss: Where Do Solar Panels Come From

The Surface Of The Solar Panel

if youve ever had a cracked or broken solar panel, you will be well aware that a sheet of glass covers the panels front face.

A special kind of toughened glass, known as tempered glass, is used for the job. Tempered glass is the perfect material for the job because it is 4-5 times stronger than regular glass, providing the panel with a strong and durable protective cover.

Tempered glass is also good for safety because when it yet breaks, it doesnt produce dangerous jagged shards like conventional glass. Instead, the tempered glass breaks into much smaller and safer pieces. This is very important if a rooftop solar panel is damaged and broken glass falls to the ground below.

Tempered glass is produced by an industrial process where regular glass is rapidly heated and cooled several times, increasing its strength.