Learning Where Solar Panels Are Made Is Part Of Ethical Consumerism

- Wesleyan University, University of California, Berkeley

David Kuchta, Ph.D. has 10 years of experience in gardening and has read widely in environmental history and the energy transition. An environmental activist since the 1970s, he is also a historian, author, gardener, and educator.

- University of Tennessee

Determining where solar panels are made is not as easy as one might think. Of the world’s top 10 solar panel manufacturers, seven are based in China, while only First Solar is based in the United States. The two remaining manufacturers on the list are from South Korea and Canada, though the latter is often considered Chinese as well.

But a manufacturer’s country of origin is only part of determining where solar panels come from. Manufacturers have factories in many parts of the world, and most manufacturers are actually just assemblers of the final product. Like many manufactured goods, a single solar panel is made of multiple parts that are manufactured by separate companies located all over the world using raw materials from even more parts of the world.

The Surface Of The Solar Panel

if youve ever had a cracked or broken solar panel, you will be well aware that a sheet of glass covers the panels front face.

A special kind of toughened glass, known as tempered glass, is used for the job. Tempered glass is the perfect material for the job because it is 4-5 times stronger than regular glass, providing the panel with a strong and durable protective cover.

Tempered glass is also good for safety because when it yet breaks, it doesnt produce dangerous jagged shards like conventional glass. Instead, the tempered glass breaks into much smaller and safer pieces. This is very important if a rooftop solar panel is damaged and broken glass falls to the ground below.

Tempered glass is produced by an industrial process where regular glass is rapidly heated and cooled several times, increasing its strength.

Sealing The Solar Cell

A completed solar cell must be sealed for protection. The compounds that are most commonly used to enclose solar cells are silicon rubber or ethylene-vinyl acetate. Silicon rubber is an elastomer or rubber-like material. Its made by combining silicon with carbon, oxygen, and hydrogen.

Silicon rubber is used widely in industry. The silicon sealant you use around the home is the same stuff. This compound is perfect for encapsulating solar panels because it is not reactive and is resistant to very high temperatures. It is also transparent which is essential to allow the cells to receive the maximum sunlight.

Ethylene-vinyl acetate or PEVA is a synthetic polymer with similar properties to silicon rubber and good alternative material used to seal solar cells.

You May Like: How Profitable Is A Solar Farm

Silicon Production And Mining Facts

-

430,000: Metric tons of silicon mined in 2018 in the U.S.

-

90%: The percent of modules sold today that use silicon.

-

468 billion: Global semiconductor sales in 2018.

-

China, Russia and the U.S. are the biggest silicon producers.

Silicon trends are on the rise and are projected to significantly increase in the next 10 years. This abundant resource comes from numerous countries and has many uses solar cell production is just one small part. Sources: USGS, U.S. Department of Energy, Semiconductor Industry Association

What Are Solar Panels Made Of

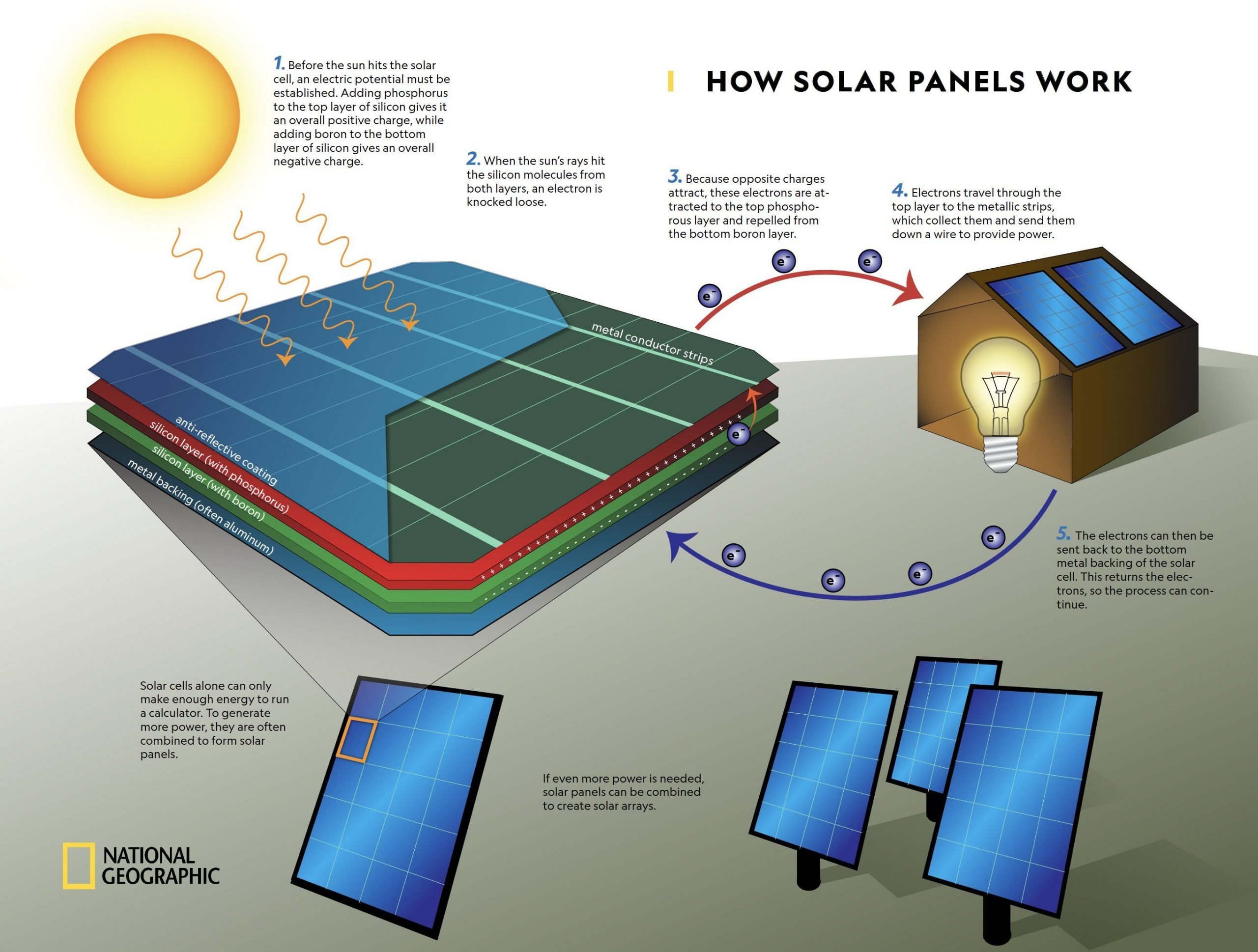

At the most basic level, the key components of a solar panel are solar PV cells, polysilicon or silicon, metal, and glass. The most important component is the solar cells which convert sunlight into usable energy. Solar cells are the photovoltaic component of solar panels, meaning they produce energy from the sun.

Solar cells are made up of silicon and are protected by a sheet of glass over the panels which allows sunlight to be filtered to the cells. When exposed to sunlight, solar silicon dioxide cells generate an electric current, which is then converted to usable AC electricity via an inverter.

Solar cells are assembled using wiring that transfers the electricity. This wiring is soldered to the cells which are then assembled between a backsheet and the glass that protects the cells. The entire panel is held together with a metal frame.

This is an oversimplified process for how solar panels are made, so lets break down the manufacturing process step by step for a better understanding.

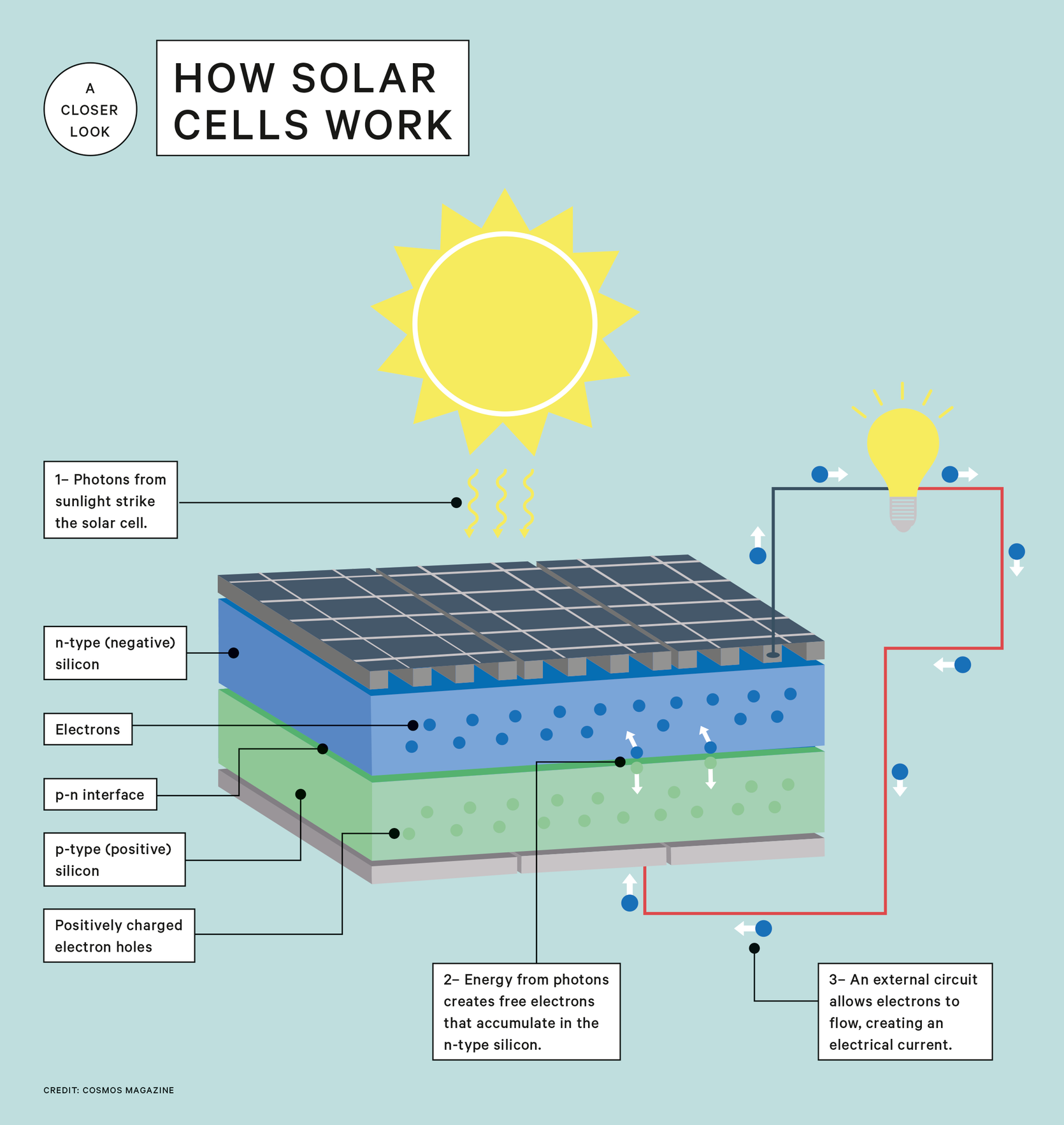

Step 1: Build solar silicon cells that are either p-type or n-type, meaning positively or negatively charged. P-type silicon cells were the traditional structure of solar cells. A p-type silicon cell is built on a positively charged base, meaning the bottom layer is mixed with boron and the bottom layer is mixed with phosphorus.

Step 2: Solder solar cells together to form one panel, usually 60 or 72 solar cells form one panel

Don’t Miss: How To Hook Up Multiple Solar Panels

Need Help Selecting A Quality Solar System

If youre considering making the switch to solar energy for your home or business, we can make your journey a much smoother ride. We offer a free online solar calculator that can project your estimated savings, payback period, system cost, and even your return on investment, and then connect you with three recommended solar installers in your local area.

Can You Make Your Own Solar Panels

For anyone wanting to install solar who is considering a do-it-yourself route, there are a number of factors to consider such as warranties, the longevity of output, efficiency and overall cost. To get a full sense of this breakdown, check out our article on the pros and cons of DIY solar. If youre looking for a personalized estimate for what a solar installation would cost based on your specific location and roof type, try our Solar Calculator. For homeowners interested in receiving quotes from local, pre-screened installers, check out the EnergySage Solar Marketplace.

Recommended Reading: Do Solar Panels Need Cleaning

When Was Solar Power Discovered

Solar energy was used by humans as early as the 7th century B.C., when humans used sunlight to light fires by reflecting the suns rays onto shiny objects. Later, in 3rd century B.C., the Greeks and Romans harnessed solar power with mirrors to light torches for religious ceremonies.

In 1839 and at the age of just 19, French physicist Edmond Becquerel discovered the photovoltaic effect while experimenting with a cell made of metal electrodes in a conducting solution. He noted that the cell produced more electricity when it was exposed to light.

In 1954 photovoltaic technology was born when Daryl Chapin, Calvin Fuller and Gerald Pearson developed the silicon PV cell at Bell Labs in 1954 the first solar cell capable of converting enough of the sun’s energy into power to run everyday electrical equipment.

Today satellites, spacecraft orbiting Earth, are powered by solar energy.

What Are Solar Farms

Solar farms, also known as solar parks or solar fields, are large areas of land containing interconnected solar panels positioned together over many acres, to harvest large amounts of solar energy at the same time. Solar farms are designed for large-scale solar energy generation that feed directly into the grid, as opposed to individual solar panels that usually power a single home or building.

Recommended Reading: How Much Does A Solar System Cost

How Are Solar Panels Made Anyway

Despite the tremendous source of energy shining in the sky, deniers keep debating and downplaying the merits of solar power and other renewable energies, asking the same questions over and over again: How effective is solar energy? Isnt it more expensive? What happens when the sun goes down or its cloudy?

Weve busted those myths before, but a question we always get is a sheepish, OK, but what are solar panels made of and are we hurting the climate by creating them?

No need to be sheepish. Its a bit complicated!

Silicon: Raw Material In Solar Cells

Silicon is the second most common element in the earths crust. According to the Minerals Education Coalition, it isnt found pure in nature rather, its found combined with oxygen in rocks such as obsidian, granite, and sandstone, in a form known as silica. Silicon can be mined from quartzite, mica, and talc, but sand is its most abundant ore source. The silicon in solar panels is manufactured through a reduction process in which the silica is heated with a carbon material and the oxygen is removed, leaving behind purer, metallurgical-grade silicon.

From there, the grade must be further purified into polysilicon, the solar-grade purity of which is 99.999 percent. To yield polysilicons of different grades, several processes may be applied to the element. For electronic-grade polysilicon, which has a higher purity percentage, the metallurgical-grade silicone must pass through hydrogen chloride at extremely high temperatures and undergo distillation. But to yield a solar-grade end product, the silicone goes through a chemical refinement process. In this process, gases are passed through melted silicon to remove impurities such as boron and phosphorus. In its pure form, solar-grade silicon is then turned into cylinders called ingots, which are then sliced into the small conductive pieces that absorb the sunlight in solar panels.

Recommended Reading: What Kind Of Solar System Do I Need

What Are The Types Of Solar Cells

Solar panels consist of silicon cells connected in an array mounted on a rigid metal frame.

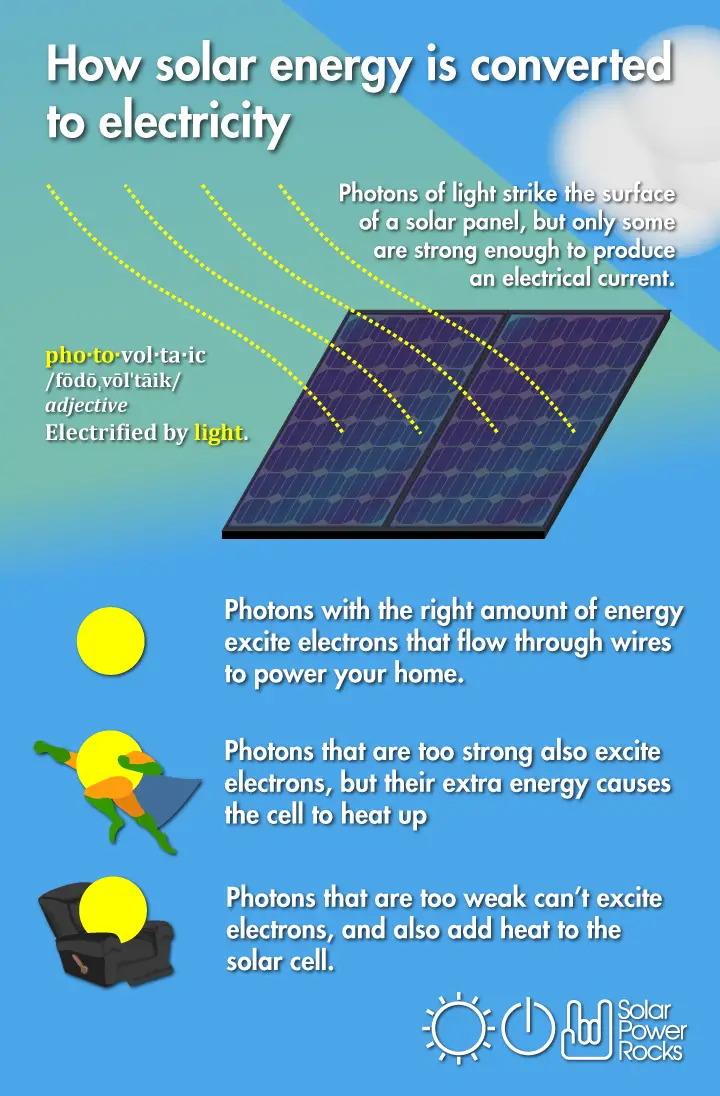

When light passes through these solar cells, they set the electron present in them to move this effect is known as a photovoltaic effect.

The frames mostly made from aluminum provide the rigidness required to keep with the harsh environment.

The silicon cells are also encased within a glass sheet to protect it from any environmental damage.

This arrangement is called a solar panel.

The silicon cells are mostly of three types Monocrystalline, Polycrystalline & Thin Film silicon cells.

Monocrystalline solar cells are silicon wafer made in one large single block format.

Solar panels made using Monocrystalline cells are considered more efficient than the polycrystalline & amorphous solar cells.

The monocrystalline solar cell production goes through a more labor-intensive process hence, theyre more expensive to make.

Monocrystalline panels have a distinct black color, which gives them a premium solar panel look.

Polycrystalline solar cells are also silicon cells that are created by melting multiple silicon cells together.

Polycrystalline solar panels are considered less efficient and less expensive than monocrystalline solar panels.

Polycrystalline cells are made by melting & pouring silicon into square molds.

Polycrystalline solar cells have a blueish color often associated with SolarWorld solar panels.

The types of thin-film silicon cells are as follows:

· Amorphous silicon cells

Lesson : How Solar Panels Work

A solar panel is made up of solar cells that are often bundled together in the panel into solar modules. A typical solar panel is made up of 60 or more individual solar cells. A solar cell is built like a sandwich. It has an upper layer and a lower layer just like slices of bread. Those layers are made of silicon, which is treated with other elements like boron and phosphorus that cause the silicon to either have too many electrons or too few of them. The solar cell produces electricity when light hits it because the energy from the light knocks electrons loose from the layer in the cell that has too many electrons. The result is that the electrical current flows from the cell

Recommended Reading: Does Having Solar Panels Save Money

Do Some States Get More Solar Energy Than Others

Obviously, some states get more sun than others. So the real question is: if weather can affect solar energy production, are some states better candidates for solar energy than others? The short answer is yes, but not necessarily because of weather.

Take clouds for example. Anyone who has been sunburned on a cloudy day knows that solar radiation penetrates through clouds. For that same reason, solar panels can still produce electricity on cloudy days. But depending on the cloud cover and the quality of the solar panels, the efficiency of the solar panels electricity production commonly drops from 10 to 25 percent or more compared to a sunny day.

In other words, solar power can still work well in typically cloudy, cold locations. New York, San Francisco, Milwaukee, Boston, Seattle – all of those cities experience inclement weather, from rain and fog to blizzards, yet they’re also cities where people see huge savings by getting solar.

No matter where you live, solar energy can be an excellent investment and an excellent way to help combat climate change. How much you’ll save – and how quickly you’ll see a return on your investment in a particular state – depends on many factors, like the cost of electricity, solar incentives available, net metering, and the quality of your solar panels.

Solar : How Solar Energy Works

Have you ever looked at the solar panels on roofs and wondered exactly what they do, and how? Well, those hi-tech expanses of shimmering glass are actually just one component in a complex network that harnesses the suns renewable energy to deliver electricity to the home within.

Lets take a simple, step-by-step look at how solar power works.

Read Also: Is Solar Really Worth It

Does It Matter Where You Buy From

You will be hard-pressed to find an American solar manufacturer whose supply chain never leaves the United States, any more than you can buy a purely American-made car. Beyond questions of the quality of materials, there are ample reasons to care about the origins of any solar panel that you may buy. Some of them are ethical or social, such as supporting countries with excellent human rights records and non-repressive governments. Examining independent supply chain reports or seeing how well a North American manufacturer fares in following the Solar Energy Industries Association’s Traceability Protocol are good places to start.

Finally, environmental, social, and governance issues are of increasing concern to investors, and many publicly traded solar manufacturers publish their own ESG reports in order to attract investors.

Step : The Cells Produce Electrical Current

Within each solar cell is a thin semiconductor wafer made from two layers of silicon. One layer is positively charged, and the other negatively charged, forming an electric field. When light energy from the sun strikes a photovoltaic solar cell, it energizes the cell and causes electrons to come loose from atoms within the semiconductor wafer. Those loose electrons are set into motion by the electric field surrounding the wafer, and this motion creates an electrical current.

Don’t Miss: How Much Are Solar Panels For A Van

Best Methods Of Cleaning Solar Panels

If you are wondering about cleaning solar panels and how much effort it might be worth, then we would consider it, as it will decrease the overall efficiency of your solar panels over time. You could see the energy consumption of your solar panel decrease by over 20% if you do not regularly maintain your panel.

Solar panels are usually built with a protective layer over the top that will make them naturally more weather resistant. Over the course of a few years, if you let dust and dirt accumulate, then you can be sure that youll have a reduced functioning solar panel.

However, there might not be enough dirt that has accumulated on your solar panel to really warrant any cleaning. If you only notice a negligible decrease in energy, then it might not be worth the extra expenditure. If your house is still totally powered by solar panels, then a clean might not be worth it.

If you have a larger solar panel on your roof, then you might suffer more losses in terms of your energy saving. Youll have to weigh up the cost of washing your solar panels effectively with the amount of money that youll be saving yourself in energy.

If you are saving yourself more energy in the long run, then we would recommend cleaning them.

How Are Solar Panels Made A Step By Step Guide

We are all aware of the term solar panels. Right?

Today, lets have a discussion on how solar panels are made.

Whats the science involved behind building this eco-friendly innovation?

Solar energy is important for our futures. It is one of the most important sources of renewable energy and the cheapest too.

The total solar energy absorbed by Earths atmosphere, oceans and landmasses are approximately 3,850,000 exajoules per year. In 2002, this was more energy produced by the sun in one hour than the world used in one year.

The amount of solar energy reaching Earth is so much that in just one year, it is twice as much as we will ever be able to get from all of the Earths non-renewable resources of coal, oil, natural gas, and uranium combined.

This all sounds very impressive but it leaves many people thinking of how these solar panels are so inexpensive, while still providing green energy.

The answer to this question lies in how these solar panels are made. But before we get into how the panels are manufactured we need to know what makes up a solar panel. Lets go step by step.

Read Also: How To Set Up A Small Solar Panel System

Turning Sand Into Pure Silicon

It all begins with creating the solar cells initially called wafers which requires turning raw sand into high-purity silicon. To do this, manufacturers use a large arc furnace running at up to 2000°C that burns away impurities and produces jagged silicon rocks. This silicon is now around 99% pure, which is perfect for most applications, but its still too low for an efficient solar cell. The rocks run through a second cylindrical furnace, which purifies the silicon further.

How To Clean Your Solar Panels Yourself

If you are going with the DIY route of cleaning solar panels and have completely checked out the safety of the situation, then we would suggest that you get some completely non-chemical cleaner and a soft sponge that will not scratch the surface of your panel.

If you inflict scratches on your panel, then you will notice a sharp drop in functionality.

Get a detergent that you know does not contain any corrosive elements, as this might eat into the glass, staining the surface and blocking out a significant level of light coming through your solar panel.

Also Check: How Much Do Solar Companies Pay To Lease Land