Poorer Quality Pv Panels:

If you buy one of the systems on Amazon or your local Costco, chances are the consumer brands arent as robust as the systems purchased by solar panel installation companies who can buy better, in bulk. If you want your system to last for a decade or a bit more this solution is probably fine. The more robust systems are expected to last up to 30 years.

Types Of Solar Panels

The three types of solar panels. Each of these types of solar cells is made in a unique way and has a different aesthetic appearance.

Each module is rated by its DC output power under standard test conditions and hence the on field output power might vary. Power typically ranges from 100 to 365 Watts . The efficiency of a module determines the area of a module given the same rated output an 8% efficient 230 W module will have twice the area of a 16% efficient 230 W module. Some commercially available solar modules exceed 24% efficiency. Currently, the best achieved sunlight conversion rate is around 21.5% in new commercial products typically lower than the efficiencies of their cells in isolation. The most efficient mass-produced solar modules have power density values of up to 175 W/m2 .

Scientists from Spectrolab, a subsidiary of Boeing, have reported development of multi-junction solar cells with an efficiency of more than 40%, a new world record for solar photovoltaic cells. The Spectrolab scientists also predict that concentrator solar cells could achieve efficiencies of more than 45% or even 50% in the future, with theoretical efficiencies being about 58% in cells with more than three junctions.

Step : The Electrical Energy Is Converted

You now have solar panels working efficiently to transform sunlight into electricity, but the electricity generated is called direct current electricity, which is not the type of electricity that powers most homes, which is alternating current electricity. Fortunately, DC electricity can easily be changed into AC electricity by a gadget called an inverter. In modern solar systems, these inverters can be configured as one inverter for the entire system or as individual microinverters attached behind the panels.

Read Also: How Many Solar Panels Do I Need For A Camper

Ok Let’s Build A Solar Panel

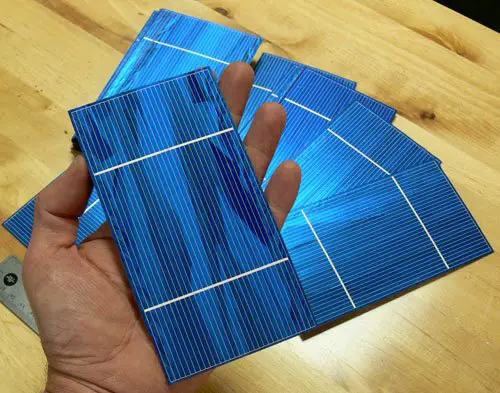

We are going to be building a solar panel with 36 solar cells in it arranged in rows of 9 and 4 like this…

Since each solar cell is rated at 1.75 watts, 36 of them wired in series will give our completed solar panel a total of 36 x 1.75 = 63 watts . This would be referred to as a 63 watt solar panel.

Free Solar Panel Plans

Step 1: Cutting Out Your Panel’s Front and Back Sides

The first step in making solar panels involves cutting out your solar panel’s front and back sides.

The front of your solar panel will consist of a sheet of clearacrylic.

The back of your solar panel will consist of a sheet of white acrylic.

Note: This material is perfect to make solar panels with because it is weather proof, corrosion proof and durable.

You must cut your pieces of clear and white acrylic to the exact dimensions of your solar panel.

So how do you figure this out?

It’s simple, whatever size of solar cells you use, you must measure them out and multiply their width by 4 and their height by 9. This will give you the approximate width and height of your two pieces of acrylic , but don’t cut yet.

You must first make sure your measurements include about a 1/4 inch of extra space in between each solar cell .

Also leave about 1 -2 inches of extra space between the outer edge of the solar cells and the outer edge of the entire panel to allow space for the aluminum frame .

Let’s put these two “cut” pieces of acrylic aside for now and continue learning how to make solar panels.

Chapter 4 Making A Solar Panel:

With enough tools and a proper technique, you can make a solar panel that is comparable or better with the one available in the market. So, In this fourth chapter, I am going to give you each and every step on how to make a solar panel.

Once you are done building your first solar panel, you can improvise with other designs and materials to improve the shape and performance of your solar panel. You can also build a custom-designed solar panel by using the techniques and steps I have provided in this chapter.

Except for the PV cells, tab and bus ribbons, other tools and materials required for building this solar panel are easily available in any hardware store. You can get PV cells, bus and tab ribbons from Amazon or eBay or Aliexpress.

Following is the list of tools, materials, calculations, and steps for building a series wired solar panel.

Here is the list of tools and material required:

| Materials Required |

|---|

| 2-position barrier block |

| Fiberboard for layout board |

Recommended Reading: How Much Is One Solid Gold Bar Worth

Solar Panel Lights Completed

The solar powered lights were finally complete!

It was a really fun project to work on. I was able to build everything within 3 days and a budget of around $250. It was expensive, but using the parts I have, I can hook up other backyard items to the solar power too.

I tested the system during the night and it worked flawlessly.

When the sun went down, the lights came on and remained on all night.

Here is the completed project:

How Solar Cells Are Made

Stage One: Purifying the silicon

The silicon dioxide is placed into an electric arc furnace. Next, a carbon arc is applied in order to release the oxygen. The resulting products are carbon dioxide and molten silicon. This will yield silicon that only has 1% impurity, which is useful in a number of industries. However, it is not yet pure enough for solar cells.

The silicon, currently at 99% purity, is not purified even further using something called the floating zone technique. A rod of impure silicon is passed through a heated zone several times in the same direction. What the procedure does is drag the impurities towards one end with each pass. At a certain point, the silicon will be deemed pure, and the impure end will be removed.

Stage Two: Making single crystal silicon

Solar cells are made from silicon boules. These are polycrystalline structures that have the atomic structure of a single crystal. The most commonly used method for the creation of the boule is known as the Czochralski method. During this process, a seed crystal of silicon is dipped into melted polycrystalline silicon. As the seed crystal is withdrawn, it is rotated, which means a cylindrical ingot, which is the boule, of silicon, is formed. The ingot is completely pure, as all impurities are left in the liquid.

Stage Three: Making silicon wafers

Stage Four: Doping

Stage Five: Placing electrical contacts

Stage Six: The anti-reflective coating

Stage Seven: Encapsulating the cell

Also Check: How Much Tax Credit For Solar Panels In California

Measure The Cell Panel

The panel used to hold the cells gives you a base measurement for the size of the box. You now need to make a backing board and the sides of the box.

For the backing board, add about 2.5 cm on every side to allow some space for the sides of the box. In addition, leave enough free space in the corner for a square piece of wood to hold the protective screen later on.

Risks Of Electrocution Damaging Home Falling From Heights:

Solar panels produce electricity and for that reason can put you and your property at risk from faulty circuits. Most systems need to be installed as a roof mount or ground mount and installing them at certain heights needed to collect the sun can be dangerous if you fall or if something falls on you. In some countries, installing your own system is illegal.

Read Also: How To Mount Solar Panels On Rv

Solar Panel Charge Controller Module

To make it easier to attach all the wiring to the charge controller, I came up with a module design that allowed the controller to be easily removed.

The charge controller was attached to a rectangular piece of wood , which was secured to the enclosure via two short deck screws.

Instead of attaching the wires from the battery, solar panel and lights directly into the controller, I opted to use a terminal block as a middle man. It was attached on the opposite side of the controller module.

Heres the front of the controller module showing the charge controller wired up and ready for action :

Heres the back of the module showing the terminal block, awaiting connections from the peripherals :

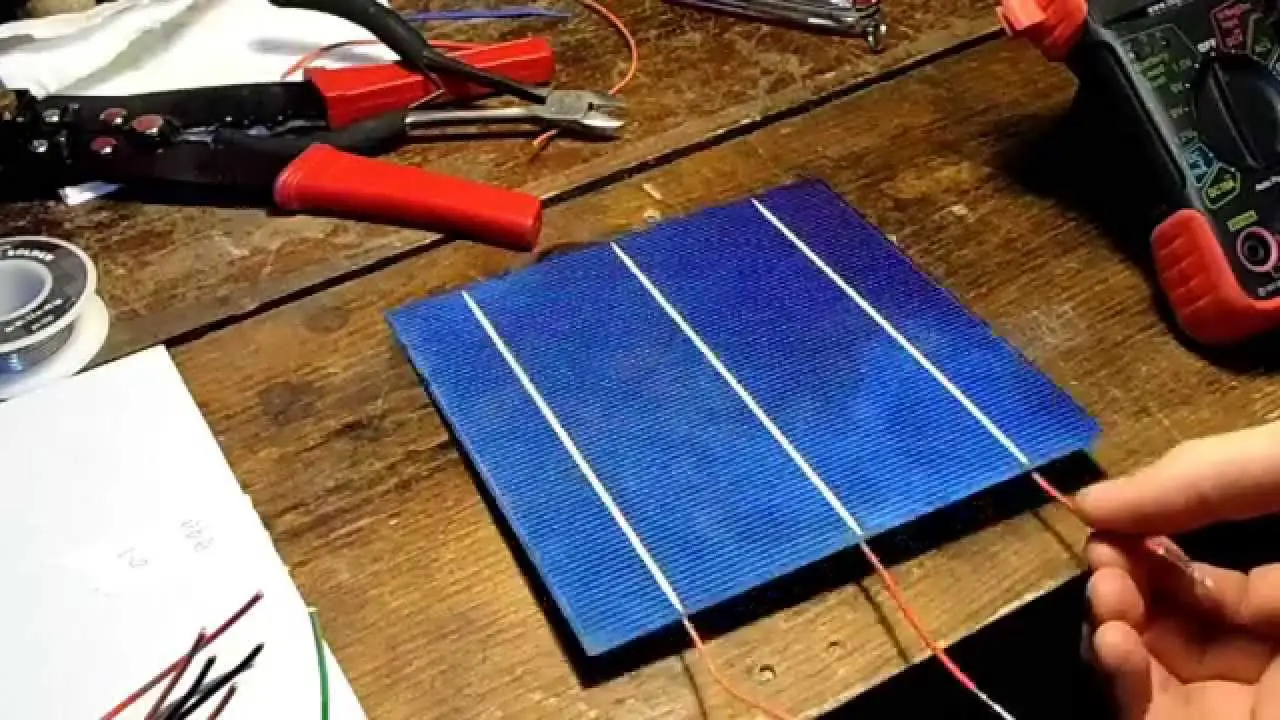

Testing Your Solar Cells

Now that you have attached the tabs to your solar cells or simply bought pre-tabbed solar cells, the next step involves testing your solar cells to make sure they are working correctly before you go any further. It is important to do this before you begin to make solar panels because one bad solar cell can ruin the effectiveness of your whole panel.

otherwise just continue with learning how to build a solar panel below.

You May Like: How Many Amps Does A 300 Watt Solar Panel Produce

Affix The Zener Diodes To The Gaps Of The Copper Wire

Once the copper wire has been fastened and completely dried, the next step would be to glue the Zener diodes. These are utilized to help in regulating the voltage.

Zener diodes must be positioned in the breaches between the cut sections of the copper wire. Solder the edges of the copper wire to the edges of the Zener diodes. Do this using a soldering iron.

It is necessary to ensure that one of the breaches is open because you will need to link the insulated wires here later.

Testing Solar Cells Output:

Before constructing the panel, you need to test each and every cell that you are going to use in your project. If you are working with off-spec, then cells need to be categorized in low, medium, and high output. One low current cells can bring the output level of other high current cells to the low rating.

Although, you dont need to get the exact output from each cell, but they should be a level of what the panel is capable of producing.

For the best results, cells need to be tested in the bright sunlight when the sun reaches above your head. But, you can test the output level of cells at any time of the year. Keep in mind, the output level will vary according to environment and weather.

Recommended Reading: Can Solar Panels Run A Whole House

Connect The Battery Holder To The Circuit Board

Now its time to connect the red wire to the red wire and the black wire to the black wire.

If you know your way around tools , now would be the time to solder the red wire to the red and the black wire to the black, but if youre not, there is no need to worry because the wire nut is here.

Take the red wire from the battery holder and put the stripped part inside the nut, then take the red wire from the circuit board where its marked BATTERY and also put the stripped part inside the nut.

Putting both of the exposed wires in the nut may not be as easy as it sounds the process requires the same focus as if you were putting a thread through a needle, so, be sure to straighten them before pushing them in.

Once you have put the red wires inside the nut, turn the nut clockwise until the wires are nice and tight.

Remove the nut carefully, and you will see an electrical bond you made without any soldering.

Put the black exposed wire from the battery holder in the nut and the black exposed wire from the circuit next to the mark BATTERY and twist clockwise until the wires form a stable electrical bond.

How To Prepare Copper

The first step is to cut a piece of the copper sheeting that is about the size of the burner on the stove. Wash your hands so they don’t have any grease or oil on them. Then wash the copper sheet with soap or cleanser to get any oil or grease off of it. Use the sandpaper or wire brush to thoroughly clean the copper sheeting, so that any sulphide or other light corrosion is removed.Next, place the cleaned and dried copper sheet on the burner and turn the burner to its highest setting.

You May Like: How To Read Aps Bill With Solar

Planning The Panel Wiring

Every solar cell has a positive and negative lead . They are marked with + for positive lead and – for negative lead. The face of the solar cell is the negative side, and the back is the positive side.

Solar cells are usually connected in strings. In the example given below, each string consists of four cells, and the panel consists of five strings of cells connected together.

Cells can be connected in two ways:

See the picture below for the difference between series and parallel connection.

Cells Connected In Series a string of four .5 volt 2 amp cells connected in series will have the output of 2.0 volts, and 2 amps at the end leads. To connect cells in a series, connect the string from the back of one cell to the face of the next cell, and so on.

Cells Connected In Parallel The same four cells when connected in the parallel can produce 8 amps and 0.5 volts. To connect cells in parallel, join the faces together. In order words, the positive side connect to the positive side of the next cell, and the negative side connect to the negative side of the next cell.

Paying Inflated Prices For Labor:

If you look at a residential solar installation teams are sent in on build days. Look online and do the math. While solar installation companies say they only charge 10% for labor, in many instances the labor is priced on par with the cost of the equipment. Do your due diligence. Then again, its not a bad thing to create some local jobs.

Read Also: What Size Cable For Solar Panels

Intro Of How To Make A Solar Panels With Cd

Have you ever wondered how the calculator in your pocket utilizing a solar panel array is?

Lights in your garden with a solar-powered generator, how exactly does it work?

How about a nifty little fun idea to repurpose the old unwanted CDs? It is an easy venture to witness to observe the futuristic phenomenon of solar power as well.

Why threaten our electricity supply by relying significantly on coal and oil?

The sun has about 5 billion years to burn to feed us endless fuel.

We have unlimited renewable energy sources utilization without depleting it and emitting pollutants & greenhouse gasses from the sun.

You can recycle the thrown away old CDs to learn more about the potential energy of the sun. So well discuss how to make a solar panel with CD? in this article.

The era of optical storage media with CD, DVD, or Blue-ray is in the end. You can now conveniently store and manage an enormous amount of digital content in the cloud and high-speed internet.

You will know how it is possible to build your solar panels with CD after reading this article. This particular piece will tell you how to make homemade solar panels with CD to produce secondary usefulness.

Youre wondering, right?

How to make a solar panel with CD?

And that raises the question, how will you benefit from this endeavor?

Powering An Island With Solar Panels In The Sea

In 2019, floating solar panels were built in the sea in the Maldives to generate electricity for a tourist resort. The 680-kilowatt system is small, but so far it is one of the larger solar installations in the sea. Research is still being done for offshore plants because storms, strong waves and salt water attack the modules much more than in freshwater locations.

Solar energy in unusual places

Also Check: Can You Write Off Solar Panels On Your Taxes

How Much Roof Space Do Solar Panels Need To Be Replaced

How much roof area is needed for solar collectors? The average solar system requires 335 to 405 square meters of roof space. To find out how much roof space your solar system needs, simply multiply the number of modules you need per square foot, which is the number of square feet of most residential solar panels sold today.

How Much Does A Solar Panel Cost

Prices have been coming down steadily over the years. The total cost will depend on how many kilowatts of power your array will generate. According to consumer reports, after solar tax credits are accounted for, the cost for a solar panel system on an average-sized house in the U.S. in 2021 ranges from $11,000 to $15,000.

Recommended Reading: Can I Get Sole Custody Of My Child

In Space With A Solar Sail

Solar cells make longer space flights possible. Solar modules can be unfolded in space and supply stations like the ISS or satellites and unmanned capsules. Researchers are even thinking about solar parks in space. Solar exploration probes have already flown as far as Jupiter. There, however, the solar radiation is 25 times weaker than in Earth orbit because the sun is so far away.

Solar energy in unusual places