What Are Solar Panels Made Of And How Are They Made

As solar energy becomes increasingly popular for residential use, youve probably had a few neighbors install solar panels and may even be thinking of getting a system for your own home. But before adopting this technology, you may be wondering: What are solar panels made of, and how are they made?

Many people simply accept that solar panels work and thats all we need to know about them, but for the scientifically and technologically curious, each individual solar panel contains a world of interesting components and materials.

Keep reading to learn more about what actually makes up a solar panel, or click below to get more information from a top solar installer.

Need Help Selecting A Quality Solar System

If youre considering making the switch to solar energy for your home or business, we can make your journey a much smoother ride. We offer a free online solar calculator that can project your estimated savings, payback period, system cost, and even your return on investment, and then connect you with three recommended solar installers in your local area.

How To Find The Lowest

Again, the best way to assess the cost of solar is to get a quote from a certified installer near you. In addition to receiving an installation price, you can learn your estimated 25-year energy costs, how compatible your home is for solar and even compare quotes to find the best offer. The simple process of getting quotes from multiple providers can save you thousands in the long run.

Read Also: Solar Power Generators For Home

Converting Raw Wafers Into Solar Cells

Each newly-cut wafer, which is less than half a millimetre thick, then gets coated with either a P-Type or N-Type layer that applies a positive electrical charge to one side and a negative charge to the other. As silicon is a naturally shiny material, each wafer also receives an anti-reflective coating to maximise its light absorption.

Grind Polish And Wafer

Once the silicone ingots have completely cooled, they are ground and polished to produce smooth, flat sides. Once the ingot is smooth and even, manufacturers slice discs, also known as silicon wafers, that are only a few millimetres thick. The silicon wafers are cut as thinly as possible to reduce waste and increase production efficiencies.

Also Check: Can You Take Solar Panels With You When You Move

A Growing Market For Solar Manufacturers

HollenderX2 / Getty Images

Following a global trend, the U.S. solar market has boomed in the past decade. Approximately 40% of all new electricity generation capacity installed in the United States in 2020 was from solar PV, up from 4% a decade earlier. In 2020, the U.S. solar industry employed roughly 242,000 people and had installed over 2 million solar PV systems.

The trend should only continue: with the extension of tax credits and other incentives, the U.S. Energy Information Administration predicts that declining costs and the pairing of solar with battery storage will lead to solar being among the most economically competitive sources of electricity.

The United States was the birthplace of the modern solar industry, due to government support for research and developmentmore than any other country. In the 1970s, 90% of solar manufacturing worldwide was based in the United States. Today, most of that manufacturing has shifted to Asia.

Latest News On Net Metering In Wisconsin

Net metering in Wisconsin as it exists today may not be around for much longer. The Wisconsin Public Service Commission is in the middle of working on a docket to consider whether net metering should continue as it is or be modified.

The PSC has asked stakeholders and the public to weigh in on whether the states current version of net metering appropriately balances the ratemaking principles of efficient price signaling, maintaining customer understanding and acceptance, equitable cost allocation, and recovery of revenue requirements. They are also considering whether current rules align with Commission and state energy policy goals.

On that last point, it could be argued that the states goal is to encourage as much solar generation as possible. The state is under a 2019 executive order from Governor Tony Evers to achieve a goal of 100% carbon-free electricity by 2050. A study conducted for the PSC in 2021 indicated that rooftop solar could account for nearly 70% of in-state electricity generation by 2034 and that a statewide net metering program would be the single best way to encourage that to happen.

RENEW Wisconsin is leading advocacy efforts in the state by organizing clean energy advocates to respond to the PSCs docket and continuing to push for smart policy to encourage renewable energy in the state.

Well keep watching the PSC to see what it does with the net metering docket, and well update this article as changes occur.

Also Check: Can You Use Pine Sol To Wash Clothes

Bottom Line: Does Solar Make Sense In Wisconsin

Lets boil it down: if youre a homeowner with a good south-facing roof or patch of land that doesnt get much shade, going solar in Wisconsin is a great idea. You can use solar power to run your homes appliances and devices while sending extra energy to the grid and getting credit for it. Just make sure you know your utilitys policy on excess solar energy.

In addition to net metering, Wisconsin offers a $500 solar rebate through the state-run Focus on Energy program, and the federal government offers a tax credit that can earn you 30% of the cost to install solar panels. Between these incentives, a solar installation in Wisconsin can pay back its cost in about 12 years and provide your home with clean energy for decades to come.

Calculate the cost of your solar system today

Can Broken Solar Panels Be Fixed

Sometimes, but often replacing the panel is the most economical solution. If it can be repaired, that’s generally done off-site.

For most problems, DIY repairs are not recommended, since these can lead to more costly problems. “I’ve seen homeowners try to re-seal cracked glass on panels,” Li says. “But if water still sneaks in, it can cause electrical problems that lead to bigger issues down the line.”

You May Like: Does A Sole Proprietor Need To Have Workers Compensation Insurance

Solar Panel Maintenance Guide

Solar panels are tough. A few years ago the Denver area experienced the most damaging hail storm in its history, yet the National Renewable Energy Laboratory and its 3,000-panel array escaped with only one cracked panel. More than 150,000 vehicles scarred by the golf-ball-size hail weren’t so fortunate.

While residential solar panels can withstand some force, they do sometimes break. They also require maintenance to keep up their efficiency and prolong their lifespan. Here’s how to keep yours in tip-top shape.

What Is Solar Panel Maintenance

Solar panel maintenance includes cleaning the glass and periodically inspecting wires to be sure they aren’t exposed or deteriorating. Conditions to keep in mind include:

- Dust and stains: Solar panels accumulate film on their glass over time, reducing efficiency.

- Debris: Branches and leaves left by storms also reduce efficiency. “After a while, those can also create hotspots, causing panels to overheat,” says Yi Li, founder and CEO of Renogy, a renewable energy company.

- Snow and ice: Accumulation on panels can cause under-cooling, which creates micro-cracks.

Also Check: What Size Inverter Do I Need For Solar Panels

Why Are Solar Panels Made With Silicone

With silicone being the predominant material used to create solar panels, the natural question to ask is: why? Silicone has been used as the semiconductor material of a solar PV panel for the majority of the solar industrys history.

When investigating all possible materials on the periodic table, developers of early and modern solar panels all found that silicone actually boasted a number of ideal properties that made it the perfect candidate as this semiconductor material:

- Silicone is abundantly available and affordable as an elemental material, making it good for large-scale systems.

- Chemically and electronically speaking, silicone is quite easy to optimize for the photovoltaic effect that efficiently converts sunlight into electricity.

- As a component material, silicone is recognized as having a long lifespan, making the investment in solar panels even more fruitful.

You can get a free, no-obligation estimate from a leading solar company in your area by clicking below.

Silicon: Raw Material In Solar Cells

Silicon is the second most common element in the earths crust. According to the Minerals Education Coalition, it isnt found pure in nature rather, its found combined with oxygen in rocks such as obsidian, granite, and sandstone, in a form known as silica. Silicon can be mined from quartzite, mica, and talc, but sand is its most abundant ore source. The silicon in solar panels is manufactured through a reduction process in which the silica is heated with a carbon material and the oxygen is removed, leaving behind purer, metallurgical-grade silicon.

From there, the grade must be further purified into polysilicon, the solar-grade purity of which is 99.999 percent. To yield polysilicons of different grades, several processes may be applied to the element. For electronic-grade polysilicon, which has a higher purity percentage, the metallurgical-grade silicone must pass through hydrogen chloride at extremely high temperatures and undergo distillation. But to yield a solar-grade end product, the silicone goes through a chemical refinement process. In this process, gases are passed through melted silicon to remove impurities such as boron and phosphorus. In its pure form, solar-grade silicon is then turned into cylinders called ingots, which are then sliced into the small conductive pieces that absorb the sunlight in solar panels.

Recommended Reading: How To Install Solar System At Home

How Solar Panels Are Made

Solar panels are made of silicon, metal, glass, and a few wires. the most important part is solar cells, which are comprised mostly of silicon and small amounts of other elements, including phosphorous, boron or gallium., They convert the sunlight into usable energy.

Cells begin by melting silicon at very high purity. Specialized machines turn that molten silicon into a cylindrical-shaped crystal called an ingot. Phosphorus and boron are added to the silicon ingot, giving it the ability to conduct electricity. Very thin sheets are cut from the silicon ingot to produce silicon wafers, which are then lined with conductive wires to form cells, which are arranged onto solar modules.

The cells are wired together and placed between a protective metal backsheet and an anti-reflective, protective glass layer. A metal frame is sealed around the panel to keep all the layers together. After assembly, a junction box is installed to protect the electrical wires in the solar panel from getting damaged. Finally, tests are run on the solar panel for quality and strength before its shipped out and installed.

Producing A Solar Cell

While silicon is the active material in a solar cell, there are a number of components that go into producing a modern solar cell. Typically the silicon is cut into thin sheets the approximate width of a piece of paper. A coating is applied to the sheets of silicon which improves the absorption of sunlight and minimising any reflection. Metal conductors are then added to facilitate the flow of electrons which are the visible small gridlines. Each cell contains a positively and negatively charged silicon wafer which meet at a conduction junction to instigate the flow of electricity.

You May Like: What Does Solar Energy Mean

The Production Of Crystalline Solar Modules

A solar PV module consists of solar cells, glass, EVA, backsheet and frame. Learn more about the components and the process of manufacturing a solar panel.

There are 3 types of solar panels available on the market:

-

monocrystalline solar panels

-

polycrystalline solar panels

-

thin film solar panels

Thus, at cell structure level, there are different types of material for manufacturing, such as mono silicon, polysilicon or amorphous silicon . The first 2 kinds of cells have a somewhat similar manufacturing process. Read below about the steps of producing a crystalline solar panel.

How Are Solar Panels Made Anyway

Despite the tremendous source of energy shining in the sky, deniers keep debating and downplaying the merits of solar power and other renewable energies, asking the same questions over and over again: How effective is solar energy? Isnt it more expensive? What happens when the sun goes down or its cloudy?

Weve busted those myths before, but a question we always get is a sheepish, OK, but what are solar panels made of and are we hurting the climate by creating them?

No need to be sheepish. Its a bit complicated!

Don’t Miss: Southern California Edison Solar Department Phone Number

Can You Make Your Own Solar Panels

For anyone wanting to install solar who is considering a do-it-yourself route, there are a number of factors to consider such as warranties, the longevity of output, efficiency and overall cost. To get a full sense of this breakdown, check out our article on the pros and cons of DIY solar. If youre looking for a personalized estimate for what a solar installation would cost based on your specific location and roof type, try our Solar Calculator. For homeowners interested in receiving quotes from local, pre-screened installers, check out the EnergySage Solar Marketplace.

How Often Do Solar Panels Need Maintenance

How often you need to clean your panels depends on their slope and the amount of dust and rain you get. Manufacturers recommend one to four times a year. But depending on your circumstances, you might get away with less effort.

“Really, the only thing I’ve done with my solar panels over the past five to six years is weed control around them, “says Carson Toews, general manager of SolarSet in Center, Colorado.

“They are angled at about 35 degrees, so the snow sheds pretty well. And even in our driest months, I don’t bother cleaning the dust off of them because it doesn’t seem to accumulate.”

Even if you’re feeling lazy about maintenance, check the system’s performance on your monitoring system periodically, and run a system diagnostic if it drops suddenly.

Don’t Miss: How To File For Sole Custody

Are Solar Panels Made Of Toxic Materials

If concerns about your panels bringing toxic materials close to your home are making you hesitate, theres no need to worry. Solar panels consist almost entirely of safe, non-toxic components. They present no risk when functioning normally. Most panels do contain microscopic small amounts of somewhat-toxic metals as part of the cells construction, but these materials remain sealed inside under all normal operations.

Related: How Long Do Solar Panels Last?

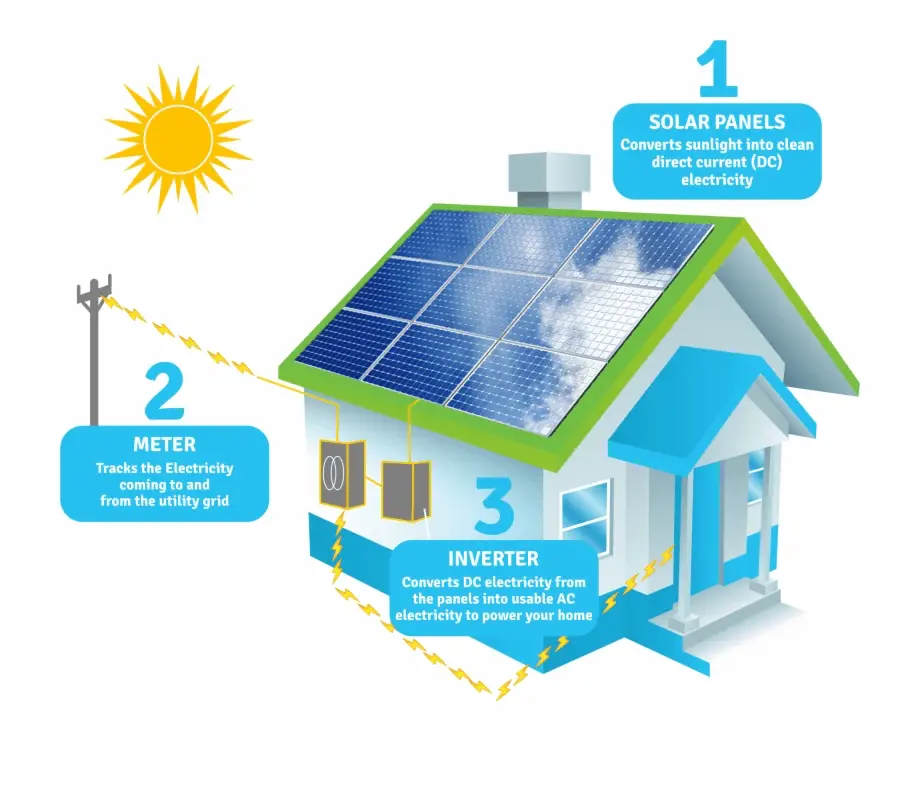

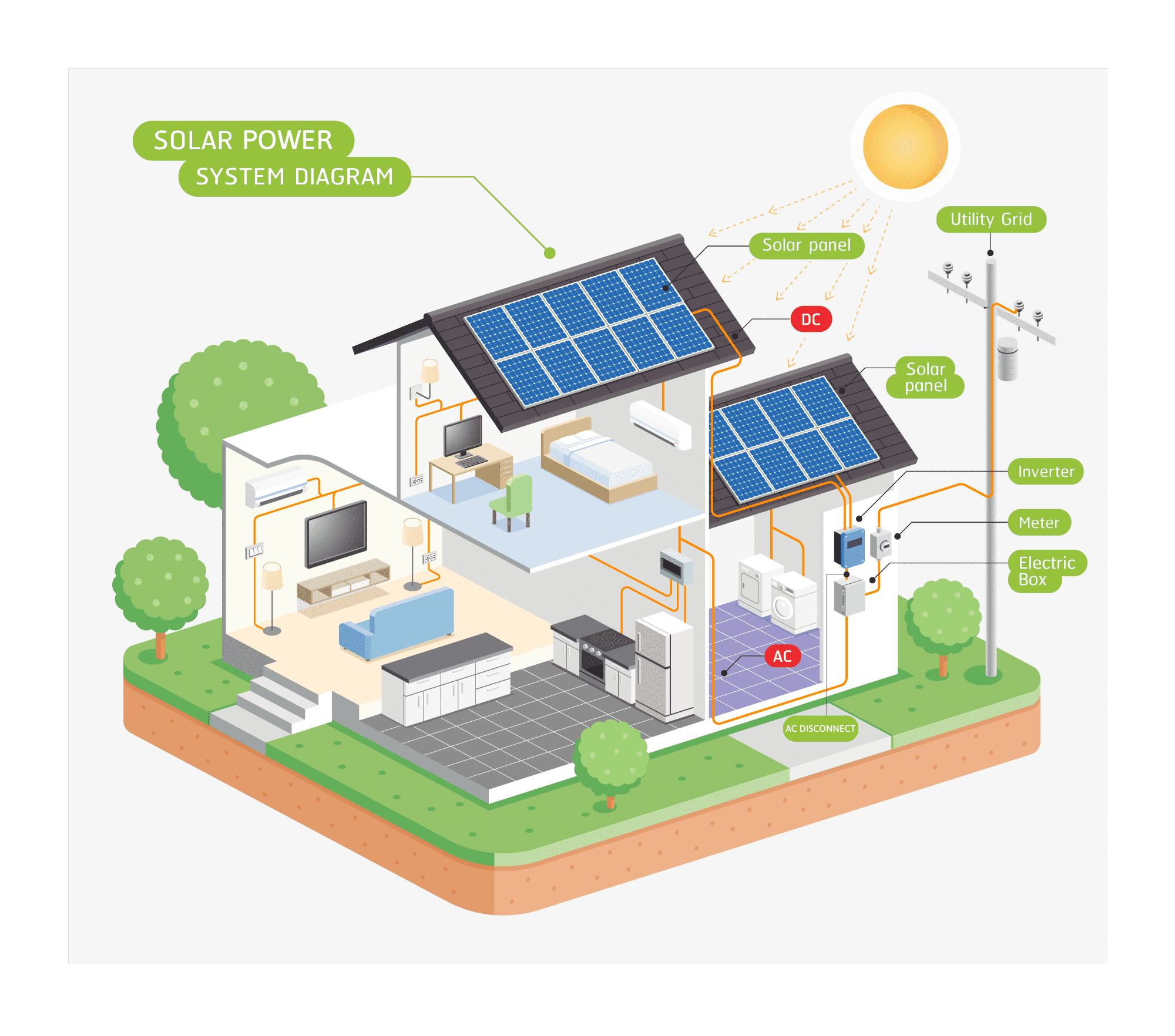

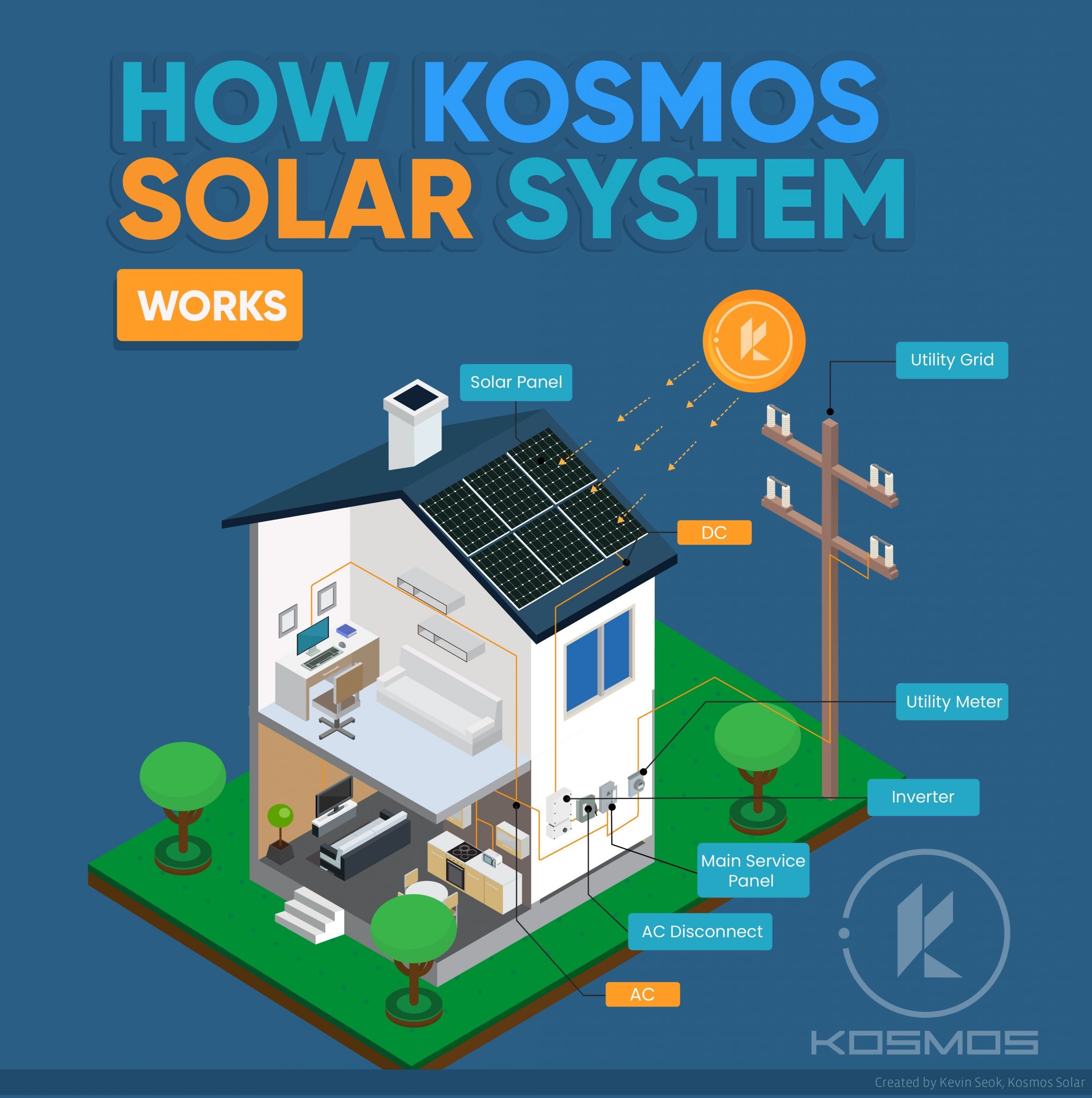

How Solar Panels Generate Power

When sunlight strikes a solar cell, the photons knock free electrons from atoms, creating a flow of direct current electricity. Tens, hundreds or even tens of thousands of solar panels can be wired together at a project, uniting that flow of electricity into a torrent. The electricity is then converted into usable alternating current with an inverter and used on-site or fed into the electric grid.

Also Check: How Much Do Solar Panels Cost In California

What Are Solar Cells

Silicon semiconductors are building blocks of solar cells. The cells absorb sunlight and convert it into electricity. They work on the principle of Photovoltaic Effect, hence the alternative name photovoltaic cells. The cells are connected electrically and put together into a large frame that makes a solar panel.

Should You Make Your Own Solar Panels

We do not recommend making your own solar panels, although it might seem easy to configure a panel with all of the proper materials. Errors in building your own panels, like starting a fire, outweigh the benefits of DIY solar panels.

It is best to rely on professionally built solar technology because they are built with rigorous standards and tested for durability. Working with a professional solar installer is an important step to making sure your solar panels are made with high-quality materials that will provide solar power for their 25-year warranty, or more. Solar panels are one of the best energy sources for reducing carbon dioxide from fossil fuels so adding them to your home is a great way to be part of the clean energy future.

Don’t Miss: How Do I Determine How Many Solar Panels I Need

Why America Doesnt Really Make Solar Panels Anymore

America invented silicon solar cells in the 1950s. It spent more on solar R& D than any other country in the 1980s. It lost its technological advantage anyway.

Every week, our lead climate reporter brings you the big ideas, expert analysis, and vital guidance that will help you flourish on a changing planet. he Weekly Planet, our guide to living through climate change, in your inbox.

You wouldnt know it today, but the silicon photovoltaic solar cellthe standard, black-and-copper solar panel you can find on suburban rooftops and solar farmswas born and raised in America.

The technology was invented here. In 1954, three American engineers at Bell Labs discovered that electrons flow freely through silicon wafers when they are exposed to sunlight.

It was deployed here. In 1958, the U.S. Navy bolted solar panels to Vanguard 1, the second American satellite in space.

And for a time, it was even made here. In the 1960s and 70s, American companies dominated the global solar market and registered most solar patents. As late as 1978, American firms commanded 95 percent of the global solar market, according to one study.

The key phrase being for a time. Solar panels arent really made in the United States anymore, even though the market for them is larger than ever. Starting in the 1980s, leadership in the industry passed to Japan, then to China. Today, only one of the worlds 10 largest makers of solar cells is American.